What Are the Key Benefits of Plastic Masterbatch?

Plastic masterbatch is an essential component in the plastics industry, providing numerous advantages that enhance the performance and aesthetics of plastic products. This article explores the key benefits of plastic masterbatch, backed by reliable statistics and data.

If you are looking for more details, kindly visit plastic masterbatch.

Enhanced Color Consistency

One of the primary advantages of using plastic masterbatch is its ability to deliver consistent color throughout produced items. According to a report by ResearchGate, the use of masterbatch can reduce color variation by as much as 90%, ensuring uniformity in large production runs. This is crucial for manufacturers looking to maintain brand identity and quality standards.

Improved Material Properties

Another benefit of plastic masterbatch is its enhancement of material properties. The incorporation of specific additives in the masterbatch allows for improved mechanical strength, UV resistance, and thermal stability. As per data from the Plastics News, nearly 80% of manufacturers reported enhanced durability in their finished products when utilizing an appropriate plastic masterbatch.

Cost Efficiency

Cost savings is a significant aspect that many companies consider when opting for plastic masterbatch. A study published by Aimpl shows that using masterbatch can reduce raw polymer usage by 15-20%, resulting in considerable savings on material costs over time. Companies can achieve enhanced performance without compromising on quality by optimizing the amount of masterbatch used.

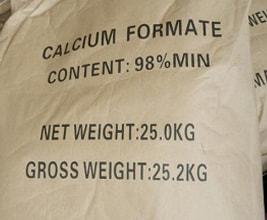

Explore more:calcium formate uses

Understanding TMAH Developer: Key Benefits and Applications in PCB Production

High Range Soundless Cracking Agent: The Ultimate Guide for Effective Demolition

10 Essential Facts About Titanium Dioxide Anatase You Need to Know

How Calcium Formate Enhances Cement Stability: Key Benefits Explained

How Does Calcium Formate for Agricultural Applications Benefit Crops?

Essential Tips for Overcoming Common Issues in Buying Iron Oxide Powder

Ease of Processing

Plastic masterbatch facilitates easier processing and handling during manufacturing. The concentrated additives in masterbatch products are tailored for consistent dispersion within the base polymer. An industry analysis from PlasticsToday highlights that more than 75% of manufacturers experience fewer processing issues, such as clumping and uneven coloration, when using high-quality masterbatches. This ultimately leads to increased efficiency on production lines.

Environmental Benefits

Recent trends emphasize sustainability in manufacturing practices. Utilizing plastic masterbatch can contribute to environmental goals by minimizing waste. According to the National Plastics, using masterbatch can result in a 30% reduction in plastic waste due to more efficient coloring and processing methods. This not only benefits the manufacturer but also aligns their operations with eco-friendly practices.

Versatility

Plastic masterbatch is incredibly versatile, making it suitable for various applications across multiple sectors. From automotive components to consumer products, the adaptability of plastic masterbatch is well-recognized. A survey from Plastics Insight indicated that nearly 60% of industries utilize masterbatches for different functionalities, including color, flame retardancy, and anti-static properties, demonstrating its broad applicability.

Conclusion

In summary, the benefits of plastic masterbatch are considerable, ranging from improved color consistency and material properties to cost efficiency and environmental advantages. As the industry continues to evolve, the role of plastic masterbatch will be pivotal in enhancing product quality and sustainability. By integrating plastic masterbatch into manufacturing processes, companies can not only improve their operational efficiency but also cater to the rising demand for high-quality, eco-friendly products.

For more information, please visit yellow masterbatch.

Explore more:What Are the Benefits of Green Iron Oxide Pigment?

Effective PAM Solutions for Clean Water Purification

Semiconductor Chip Manufacturing: Continental Methods vs. Asian Techniques

Understanding Lithopone: Uses, Benefits, and Manufacturing Process Explained

7 Essential Facts About Electronic Chemicals Manufacturers You Need to Know

Is Sorbitol a Sweet Solution for Health?

Future Innovations: PU Material for Fracturing Valves in 2025